Gripple, a manufacturer of engineered suspension solutions, presents Fast Trak—a system designed to support mechanical and electrical installations on construction sites.

Fast Trak allows projects to be completed up to six times faster compared to traditional methods using threaded rod or channels. By reducing the need for on-site cutting of channels, it can also lower labour time and the associated risk of injuries.

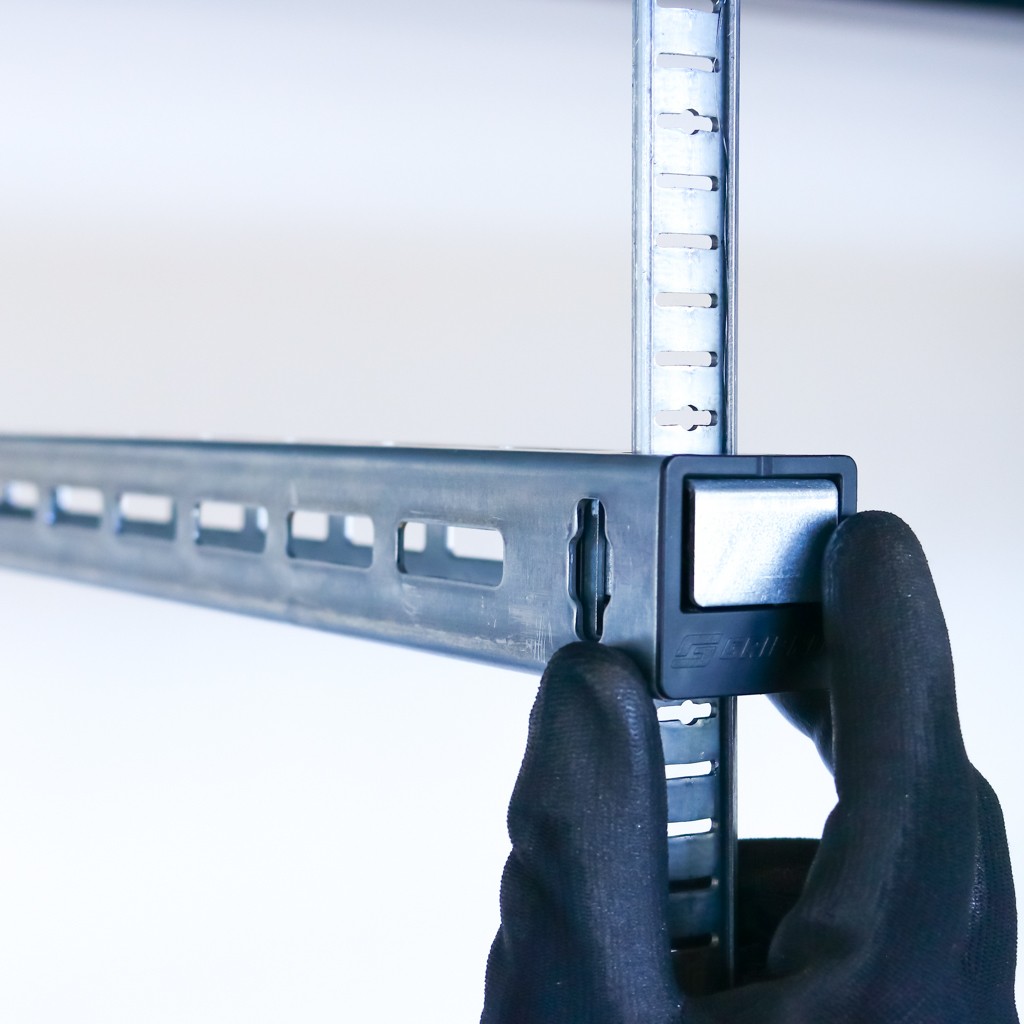

Engineered for adaptability, Fast Trak’s tool-free adjustment system enables installers to make position changes along the tracks without additional tools. Excess track can be neatly tucked or removed after levelling, providing a streamlined finish.

The system includes a four-sided bracket that allows attachments on any side, supporting multi-tiered installations. Built-in measurement indicators and levelling markers on the tracks facilitate accurate marking and levelling on-site.

Fast Trak is pre-sized and prefabricated, reducing the need for large rods or struts and limiting on-site storage requirements. Compact packaging with integrated handles makes the components easier to transport around the job site.

Fast Trak supports working loads up to 650 lbs. A variety of bracket and track lengths allows contractors to tailor installations to site requirements, accommodating both uniformly distributed loads and single-point loads.

The system holds ICC-ESR-4622 and IAPMO approvals and meets MFMA and DSA/OSHPD codes. It has also undergone fire testing to F120 and MPA 1363-1 standards.

Fast Trak provides a modular suspension system designed for efficiency, flexibility, and durability in construction installations, supporting a range of mechanical and electrical project requirements.